1. The longitudinal and transverse sealing cutters have four groups of independent temperature controllers, which are made of OMRON brand in Japan and can be adjusted directly and independently.

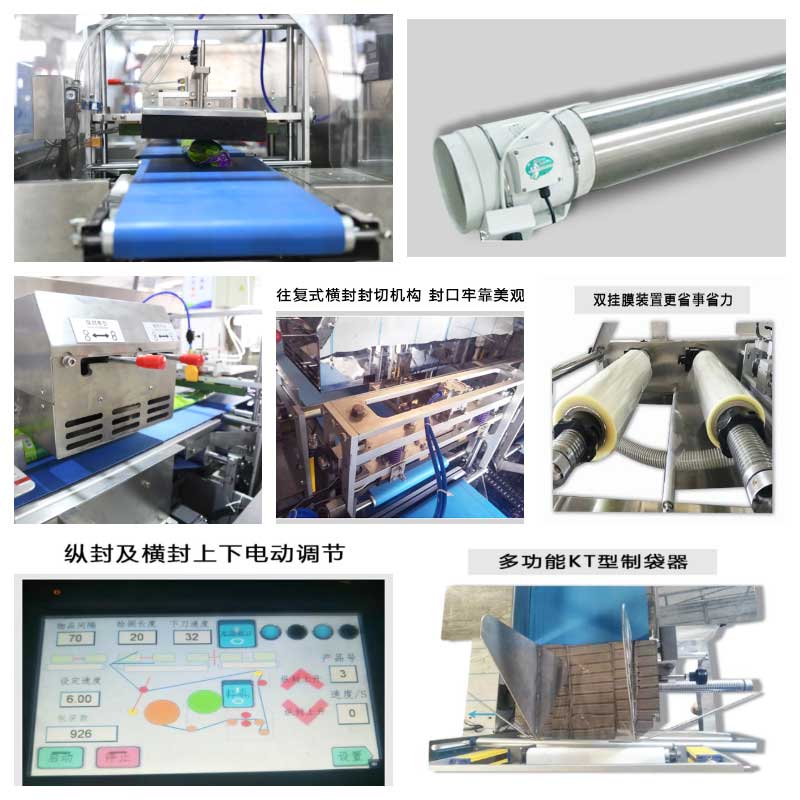

2. Reciprocating cutter structure, longer sealing movement time, firm sealing, can track the synchronous movement of packaging materials, sealing and cutting, up to 150mm past the packaging materials.

3. The input conveyor and main machine of the packaging machine are made of 304# stainless steel, which is convenient for cleaning and has long service life to prevent rust and aging.

4. Imported PLC full computer control system, man-machine interface, 10.1-inch large LCD touch screen.

5. The leaf vegetable packaging machine adopts four servo AC motors of Mitsubishi brand in Japan to separately control the conveying input, film feeding rod, reciprocating middle belt and transverse sealing and cutting knife, so as to control accurately and stably, and realize automatic detection of vegetable length for bag making, sealing and cutting output packaging.

6. Vertical punching is adopted in the process of packaging vegetables, so as to keep the vegetables fresh.

7. The company adopts humanized design. When workers do not place materials, the machine stops. When materials are detected, the machine starts automatically without empty bags, which greatly saves the cost of consumables.

8. It is easy to replace vegetables with different widths. Just rotate the knob on the KT bag maker to complete the width adjustment.

9. It can be completed automatically; The whole packaging process of bag making, counting and punching, and finished product output.

10. The imported food grade PU material conveyor belt has no deformation after long-term use, acid, alkali and oil stain resistance, and the wear resistance is 3 times longer than that of the domestic grade conveyor belt of the same kind

above. Both sides of the leafy vegetable input conveyor adopt belt type to escort materials, which can effectively prevent the astringent feeling caused by vegetable feeding, reduce friction and ensure the safety of leafy vegetables

It will not be damaged in the process of conveying and packaging.

11. The electronic transverse sealing adjustment technology can control the height of the transverse sealing cutter through the microcomputer. The operation is simple and flexible. It is suitable for the automatic packaging of leaf vegetables with different heights.

12. The width of the worktables on both sides of the conveyor can be adjusted freely through the man-machine interface to facilitate the packaging of vegetables with different widths

13. Automatic air blowing device for bag forming to reduce transverse sealing wrinkles.